Veneers must be glued to something – that’s a substrate!

The substrate is the material that the veneer is glued on to. In general, common veneer substrates are either medium density fiberboard (MDF), particle board, plywood, or other less expensive pieces of wood such as poplar or pine.

Typically a wood substrate is a product made of solid wood, particleboard, plywood, MDF. Less frequently the substrate material may be rattan, wicker, bamboo, or other composite products.

Sometimes no substrate is used and veneers are glued (or bonded) to each other. This is how plywood is made.

Technically, any smooth surface that can be glued to can be used as a substrate for a wood veneer.

What are the qualities that make a substrate suitable?

What you are looking for is a substrate that is stable (does not expand and contract with temperature or moisture changes) and is as flat as possible. It also needs to accept an adhesive that will keep flat as well. Although solid wood can be machined to be flat, it will not have the stability that a manufactured man-made material such as MDF has.

What is the best substrate to use for veneer?

Although your project might require a specific substrate, by far the most commonly used and best substrate is MDF.

MDF is smooth, flat, and incredibly stable. It is also relatively inexpensive and consistent in its make up. Its surface readily accepts being glued to veneer. What makes MDF the best substrate is that the fibers within the board have no orientation and so will not expand the panel in any direction (unlike a wood board would expand across the grain).

If you can’t get MDF, then particle board or OSB is also suitable because these panels also have no overt expansion issues.

Which is a better substrate; plywood or MDF?

Both plywood and MDF are very suitable to use as substrates, the different characteristics mean they are each best suited to different purposes. For example, MDF is the choice for cabinet doors and is also used as a wall and ceiling substrate. Plywood however is the preferred choice for joinery units, showing off the ply edge grain and as a sustainable, natural option for walls and ceilings.

Is there any preparation to be done to the MDF substrate before veneering?

As in any woodworking application, the moisture content must be reasonable before any veneer is applied. It is also preferable to lightly scuff sand the MDF before veneering.

What about particle board as a substrate?

Particle board is also a good substrate, however if it has a melamine surface, a proper glue bond can not be applied to this surface. It will need to be sanded first.

Can I use plywood as a substrate?

Although plywood is not as good a choice as MDF it can be used as well. If weight is an issue, for example on large doors, baltic birch plywood can be used instead of the heavier MDF. However, plywood can warp, especially if stored improperly, and may have voids within its core that you may not see until it is cut.

Can I veneer over solid wood?

You can also veneer over solid wood if necessary, but it is obviously more expensive and less stable than MDF. Lay the veneer in the same grain direction of the solid wood. This will keep the wood movement together and will reduce problems from arising in the future due to expansion and contraction from moisture.

Veneering has a long history and before the advent of modern technology and the manufacturing of large panels such as MDF and plywood, all wood veneering was done onto solid wood. If done properly, it can last centuries.

When a solid wood substrate is used, quarter-sawn or rift cut lumber is best because it has less seasonal movement than lumber that is flat cut.

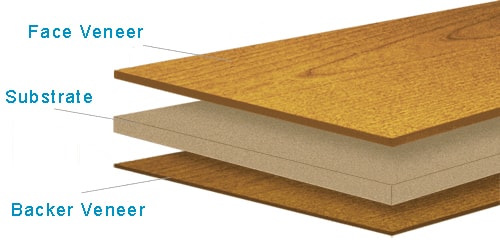

What is a backer veneer?

A backer veneer is necessary to even out the tension on the substrate that the veneer produces. It helps stabilize the substrate basically. If you only veneer one side of the substrate, the substrate can warp over time. The backer veneer does not have to be high quality and can be a much lower grade or material if the back of the panel will never be seen. The basic rule is that whatever you do to one side of the panel, you need to do to the other side. This includes the finishing as well, so for example moisture enters and exists the panel equally on both sides, again to avoid warping.